Introduction

Preservatives play a vital part in almost all cosmetic formulations. Their efficacy is needed in products with high water content as microorganisms present in our environment or on human skin can enter and multiply in products as a result of their production and use. This will lead to a contaminated product which will negatively influence the consumers use experience. Moreover those germs and bacteria in contaminated products can cause various adverse reactions in the skin, ranging from allergies to inflammation or eczema and in rare cases – particularly in immunosuppressed individuals – even life threatening diseases.

Preservatives – State of the Art

There are almost endless options to choose from when searching for the right preservative system – some with better and some with worse standing in the public opinion. The largest market share of the traditional preservatives is still reserved for Phenoxy-ethanol. This substance was once established to act as a solvent and co-preservatives for Parabens in preservation blends and later it was positioned as a stand-alone alternative to Parabens. The latter have lost their momentum because of controversial opinions on their safety, based on concerns that they could disrupt the body’s natural hormonal balance and cause adverse reactions in the body, such as breast cancer. Though those assumption have not been scientifically clearly proven, these preservatives have been heavily phased out and a downward trend in market share can be seen.

Most of the time one preservative alone is not effective enough, which is why they are often combined with other antimicrobials classified as preservation boosters. These so called boosting agents are being used more and more frequently in cosmetic products, as their application concentration tends to be lower, but the effect of these additives is considerable and better results are usually achieved with their help in preservative efficacy tests (PET), also known as challenge tests. Looking at market data for preservative boosters, Caprylyl Glycol and Ethylhexylglycerin combined cover the largest market share with more than 70% and an upward trend can be observed for both of them.

One explanation for the widespread use of Phenoxyethanol, Ethylhexylglycerin and Caprylyl Glycol are the famous Phenoxy-ethanol blends, combining the former with each one of those boosting agents. Even though Phenoxyethanol is one of the most widely used preservatives and formulators prefer its use due to its potency and easy application, it has lost its reputation with consumers over the last couple of years.

Phenoxyethanol is listed as a preservative in Annex V of Regulation (EC) No 1223/2009 for cosmetic products and can only be used up to 1.0% according to this guideline. Formulators are trying to step away from listed preservatives more and more, because the consumer is pressuring to do so, even though at those concentrations they are considered safe and well tolerated.

Up until now, finding an alternative for the widely used Phenoxyethanol was not crowned with success, but the search could now be over and the solution might be found in the group of aromatic alcohols …

Aromatic Alcohols and their Function

Aromatic alcohols are well known for their masking properties and as fragrance compounds, but are even more used for their preservative effect. Due to their amphiphilic structure they are able to interfere with membranes of microorganisms as well as disturbing vital processes inside a microbes cell, as they are able to inhibit important enzymes, which ultimately results in the elimination of the microbe.

One famous representative of this group is Benzyl Alcohol, which is a well-known preservative and fragrance compound. However due to the fact that it is also classified as an allergen, a listed preservative and therefore restricted in its percentage of use, it is not always the first choice of formulators.

A less well known representative of this group is Phenethyl Alcohol. It can be sourced from petrochemical origin, as well as natural sources and, in contrast to Benzyl Alcohol, it is not classified as an allergen or a listed preservative, already giving it a huge advantage.

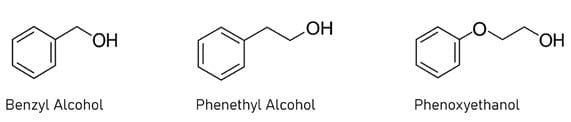

Looking at the chemical structure from Phenethyl Alcohol and comparing it with the molecules of Benzyl Alcohol, as well as Phenoxyethanol (Fig. 1), it can be recognized that they are very similar in structure. Being related in chemical structure, functional groups and molecular size, a similar efficacy in the preservation effect may be expected.

With this in mind we developed two Phenethyl Alcohol blends that could act as an alternative for the Phenoxyethanol blends with Ethylhexylglycerin and Caprylyl Glycol: Evicide® rose 26 (INCI: Phenethyl Alcohol, Ethylhexyglycerin) and Evicide® rose 8 (INCI: Phenethyl Alcohol, Caprylyl Glycol).

To verify a technical equivalency we compared the efficacy of corresponding Phenoxyethanol blends with Evicide® rose 26 and Evicide® rose 8 in several formulations and with different pH values using preservative efficacy tests.

Fig. 1: Chemical structures of Benzyl Alcohol, Phenethyl Alcohol and

Phenoxyethanol

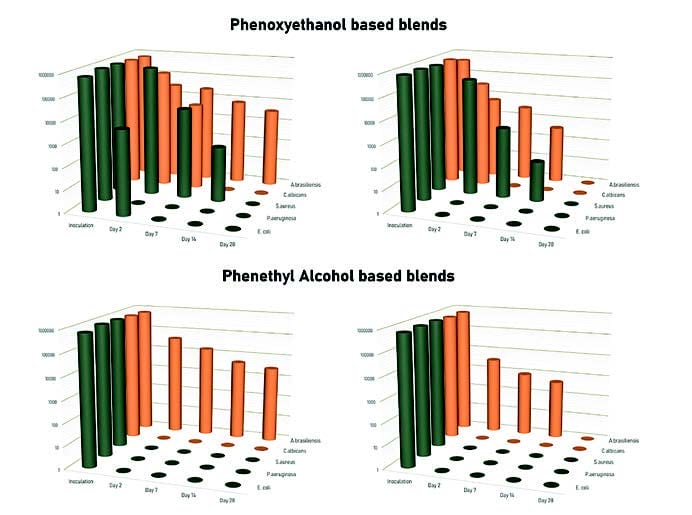

Fig. 2: Comparison of challenge test results for O/W emulsions with an pH-value at 5.5. Top left:

Evicide® PEHG (1.0%) with final grade B;

top right: Evicide® PCG (1.0%) with final grade B;

bottom left: Evicide® rose 26 (1.0%) with final grade A; bottom right: Evicide® rose 8 (1.0%) with final grade A

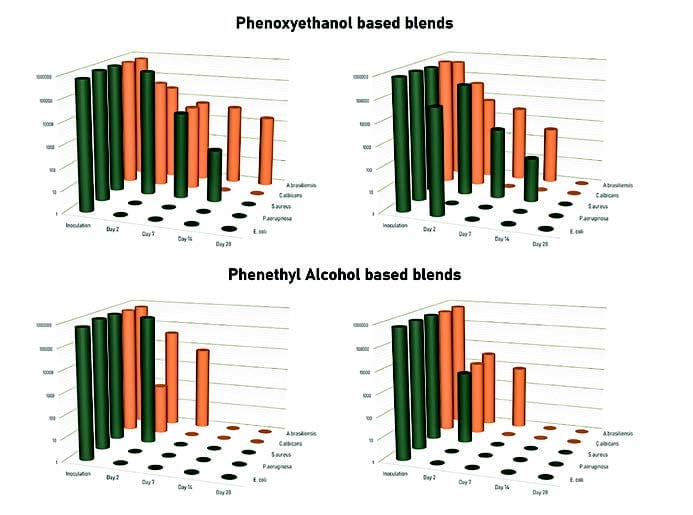

Fig. 3: Comparison of challenge test results for O/W emulsions with an pH-value at 7.0.

Top left: Evicide® PEHG (1.0%) with final grade B;

top right: Evicide® PCG (1.0%) with final grade B;

bottom left: Evicide® rose 26 (1.0%) with final grade B;

bottom right: Evicide® rose 8 (1.0%) with final grade A.

Phenethyl Alcohol Blends Achieving Better Results in PET

In the following, four O/W emulsions were subjected to a challenge test with five different microorganisms (A. brasiliensis, C. albicans, S. aureus, P. aeruginosa, E. coli) for a period of four weeks (EP standard). Each emulsion contains 1.0% of the specific preservative and has been adjusted to pH 5.5 after preparation. The first two formulations are Phenoxyethanol based with Phenoxyethanol, Ethylhexylglycerin (Evicide® PEHG) and Phenoxyethanol, Caprylyl Glycol (Evicide® PCG), while the other two formulations are Phenethyl Alcohol based with Phenethyl Alcohol, Ethylhexylglycerin (Evicide® rose 26) and Phenethyl Alcohol, Caprylyl Glycol (Evicide® rose 8).

As pictured in Fig. 2, the concentration of 1.0% Evicide® rose 8 or Evicide® rose 26 is enough to show a significantly larger reduction in the bacterial count, compared to the Phenoxyethanol based formulations.

Similar results were achieved in the four O/W emulsions at pH 7 (Fig. 3). The formulation with 1.0% Evicide® rose 26 showed a quicker reduction in bacterial count compared to the formulation with 1.0% Evicide® PEHG. Also the formulation with 1.0% Evicide® rose 8 showed a quicker reduction in bacterial count compared to the formulation with 1.0% Evicide® PCG, resulting in an A grade, whereas the PCG formulation only passed with a B grade.

| Preservative blend | Final PET Grade | |

| pH 5.5 | pH 7.0 | |

| Evicide® PEHG | B | B |

| Evicide® rose 26 | A | B |

| Evicide® PCG | B | B |

| Evicide® rose 8 | A | A |

Comparing all resulting grades of those four challenge tests (Table 1), it can be concluded that the Phenethyl Alcohol based antimicrobial blends are not only an equivalent alternative but can even be more efficient than Phenoxyethanol based preservatives, when used in emulsion applications.

In addition, further challenge tests were performed (Table 2 and Table 3) in order to be able to make a broader statement about the preservative properties in different formulation types. All four preservative blends were tested in a bodywash formulation. Even though there are more effective preservative systems for surfactant based formulations, such as organic acids, a lot of formulators are using Phenoxyethanol based preservatives for those formulation types. This is why bodywash formulations were incorporated in the conducted challenge tests. The formulations were tested with two different pH values, once at 5.5 and once at 7.0. Each preservative was incorporated into the formulation at a concentration of 1.0%.

It can be seen here that all formulations, with the exception of one, finished with a challenge test result of A. The bodywash formulation with 1.0% Evicide® PEHG failed at pH 7.0 due to the fact that the E. coli counts did not decrease enough and on day 21 it even increased. This could be due to a variety of reasons, such as incompatibility with surfactants, as explained earlier. Phenethyl Alcohol based antimicrobial blends can be seen as an equivalent alternative with a more or less similar efficiency than Phenoxy-ethanol based preservatives, when used in surfactant based products.

Summary

All in all it can be stated that the Phenethyl Alcohol blends Evicide® rose 26 and Evicide® rose 8 are not only a better option concerning the regulatory perspective, as they aren’t classified an allergen, like Benzyl Alcohol or a listed preservative, but are in total a more efficient preservative system compared to the well-known Phenoxyethanol blends: In surfactant based formulations similar results were obtained, and in emulsions they were able to show even better and quicker results in the conducted challenge tests, compared to the Phenoxyethanol equivalents.