Summary

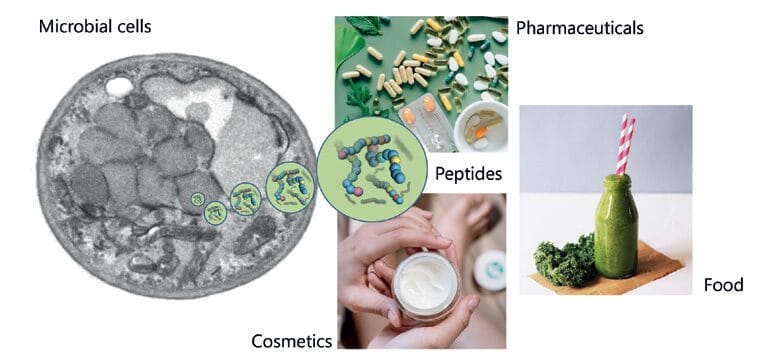

Short peptides not only play crucial roles in living organisms, but these biomolecules are also important for different industrial markets. Although they have many benefits, there is a downside, since current chemical and biological production techniques are environmentally unfriendly and costly – especially in large quantities. Therefore, the Austrian Centre of Industrial Biotechnology (acib), and particularly the working group of Dr. Anita Emmerstorfer-Augustin focus on the engineering of biotechnological production hosts such as Pichia pastoris. The goal is to enable a more sustainable production of peptides to meet the demands of the pharma, cosmetic and food industries.

Introduction:

In every living organism – or in every cell – peptides are present. These remarkable biomolecules consist of two or more amino acids linked in a chain and play crucial roles in cell communication, both within individual cells (intracellular communication) and among cells (intercellular communication). Typically, short peptides consist of 5–100 amino acids, and they have many important and diverse roles – both for human health but in different industrial applications as well. For example, they can display antimicrobial or antiviral activity, act as hormones, regulate proteins, function as flavor compounds in food products or serve an important role in cosmetics and vaccines. Although there are different natural peptides produced in the human body, most short peptides – especially for industrial products – are synthesized chemically via solid phase synthesis. However, this method poses several challenges, as it is not only environmentally unfriendly but also costly, particularly when targeting large-scale production. Since most short peptides are encoded genetically in their original host system, a recombinant production – e.g. in yeast, insect- or animal cell lines as biotechnological hosts – is an attractive alternative, which, among other economic advantages, can also easily be scaled up. However, diverse shortcomings currently limit this possibility, e.g. low yields due to peptide proteolysis, degradation, aggregation, or cytotoxicity towards the production host. Taken together, these major obstacles of chemical and biological synthesis limit a broader commercial application of microbially produced short peptides at the moment.

New production methods for peptides

To overcome these obstacles, acib is working on innovative new methods, primarily focusing on the engineering of microbial systems. Anita Emmerstorfer-Augustin, Scientist and Group Leader at the Austrian Centre of Industrial Biotechnology (acib) explains: “We are using the yeast Pichia pastoris (syn. Komagataella phaffii), which is especially known for its powerful and efficient protein secretion machinery, as production host.” To avoid cytotoxicity and to facilitate downstream processing, short peptides will be secreted into the culture supernatant. “Currently, we are working on different strategies to fully understand the secretory pathways of short peptides. The secretion of short peptides seems to differ from those of larger, fully folded proteins, and there is certainly a lot we can learn in terms of pathway engineering.” The secretion signal sequences, necessary for targeting a peptide or protein into the secretory pathway, also significantly influence the success of secretion. Therefore, acib explores novel signal sequences for efficient secretion and correct processing of short peptides. “Especially for commercial applications, peptides have to be produced with their exact N- and C-termini, which means that signal sequences required for secretion have to be removed efficiently”, says Emmerstorfer-Augustin. Another problem of peptide biosynthesis is proteolysis, a process in which a protein is broken down partially into smaller polypeptides or amino acids. This problem could be reduced by using special protease-deficient strains. The use of P. pastoris as a production host additional poses advantages in terms of sustainability. As a methylotrophic yeast, P. pastoris can utilize methanol as its sole carbon source. Methanol is a primary product of current carbon capture technologies, making it particularly advantageous as a microbial C1-feedstock, thus supporting a circular economy. “In combination, our proposed strategies will allow for both higher yields and purities of short peptides than currently available technologies. This will make these biomolecules more cost-efficient and affordable for various industries”, highlights Emmerstorfer-Augustin the importance of these new, biotechnologically produced peptides. “The production processes aim for a much lower carbon footprint than traditional chemical synthesis, plus the peptides we produce are natural and vegan.“

High demand of different markets

One of the highest demands for peptides is to be found in the pharmaceutical market: The demand for peptide drugs has increased at a cumulated annual growth rate (CAGR) of 9.5% over the last couple of years. This means that peptide drug sales are estimated to exceed 50 billion USD in 2024 alone. Besides, further applications for short peptides are under development including (personalized) peptide vaccines, pesticides, cosmeceuticals, nutraceuticals, coatings, biosensors or antibiotic substitutions to name a few other markets.

Broadly applicable, environmentally and economically favorable production platforms

“In order to satisfy the increasing demand, synthesis methods have to be scaled up, which is barely feasible for conventional solid-phase synthesis”, Emmerstorfer-Augustin knows. As sustainability continues to gain prominence in future industrial production processes, its impact will be most pronounced in sectors heavily reliant on significant quantities of organic solvents and other hazardous chemicals. Biological peptide synthesis provides companies with a competitive edge, offering substantial sustainability benefits that resonate with environmentally conscious consumers. “Another advantage is that we expect our technology to be transferrable to almost all genetically encoded peptides of interest”, Emmerstorfer-Augustin further explains. The new peptides production platforms will be price-competitive, economically favorable, and offer an advantage in technology for companies focusing on peptide synthesis. Asked, which target groups or companies could be interested in the new technology, Anita Emmerstorfer-Augustin answers: “I think many different companies will be interested in the development and production of short peptides in the future, be it companies in the pharma, healthcare, or food industries. An insider from big, renowned pharma company just recently let me know that microbial production strategies would be an interesting alternative to current production methods, especially when it comes down to peptides built from >20 amino acids and when needed to be produced at large quantities (>100 kgs/year).” Acib in general notices a strong interest in more sustainable production processes for short peptides, and works on other strategies, including the incorporation of non-canonical amino acids and the use of specialized proteases for purification and further processing. “At the current stage we are seeking for interested partners to further develop our technology and to investigate the potential of these peptides, e.g. antimicrobial peptides in the treatment of neurodermatitis or short peptides for the alternative meat market, e.g. beefy meaty peptides. We are very optimistic that the new, environmentally friendly and economically promising production platform of peptides will open up the future to various innovations and applications for our everyday life.”