Introduction

In the dynamic landscape of personal care product manufacturing, achieving optimal formulation stability and performance is crucial for meeting consumer expectations and regulatory standards. Emulsions, serving as the backbone of numerous cosmetic and skincare products, rely heavily on emulsifiers to impart stability, texture and sensory feel. However, the diverse demands of modern formulations, coupled with evolving consumer preferences and stringent regulatory requirements are resulting in enormous challenges for manufacturers. Addressing these challenges requires a nuanced understanding of emulsifier systems and their synergistic interactions.

Most of the time one emulsifier is not enough to build a complex emulsion, as stability relies heavily on a small and continuous droplet size distribution in the outer phase of an emulsion. Most of the time one emulsifier is not enough to build a complex emulsion, as stability relies heavily on a small and homogenous droplet size distribution in the outer phase of an emulsion. Using more than one amphiphilic substances as the emulsifier will improve stability, however manufacturing time and handling will be negatively affected at the same time. Using more than one amphiphilic substance as the emulsifier system will improve stability, however manufacturing time and handling will be negatively affected at the same time. For this reason emulsifier blends, comprising a combination of two or more emulsifying agents, have emerged as a strategic tool for formulators seeking to navigate the complexities of product development.

Additionally, the importance of emulsifier blends goes beyond the optimization of formulations and includes further considerations such as sustainability and consumer safety. With growing awareness regarding environmental impact and ingredient safety, manufacturers are under rising pressure to develop products that are both effective and eco-conscious.

This paper discusses the pivotal role of emulsifier blends in cosmetic product manufacturing, shedding light on their multi-faceted advantages, including enhanced stability, improved texture, prolonged shelf-life, and heightened compatibility with diverse ingredients. We present a study aiming at the development of new all-natural O/W emulsifier blends based on a mixture of anionic Glyceryl Stearate Citrate, non-ionic Cetearyl Alcohol, and two Glyceryl Esters with fatty acids of varying C-chains – namely Glyceryl Laurate and Glyceryl Behenate. The effect of the different carbon chain lengths on the emulsion properties are investigated and contrasted. We aim to provide formulators and researchers with a comprehensive framework for harnessing the potential of emulsifier blends in the pursuit of innovative, efficient, and sustainable personal care solutions.

Natural emulsifier systems and their properties

Emulsifiers have the ability to lower the surface tension between water and oil and thus allow for the formation of very small droplets of one liquid (the dispersed – or inner – phase) in the other (the continuous – or outer – phase). Thus, the two liquids are still not really dissolved in each other, but are forced into very close contact in a homogeneous dispersion, the emulsion. Ever since scientists have started to prepare emulsions, there has been the need for potent emulsifiers. Technology has evolved from the first emulsifiers that have been found in nature (Lecithins) to modern emulsifiers which show an improved performance. Today a large variety of non-ionic and anionic emulsifiers, and to a lesser extend cationic emulsifiers, are employed. In line with global consumer trends, there are many vegetable based, sustainable emulsifiers on the market with different properties and sensorial profiles. Still, as outlined above, a continuous need for new emulsifier mixtures is still needed.

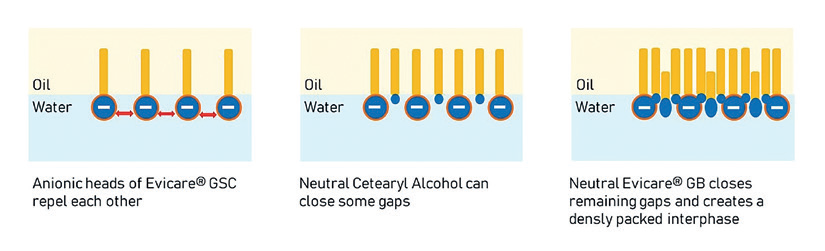

One of the most well-known natural and food grade O/W emulsifiers is the anionic emulsifier Glyceryl Stearate Citrate. While it is considered a robust emulsifier, due to it’s anionic nature and the associated repulsive forces at the interphase (figure 1), further stabilization is required. Moreover Glyceryl Stearate Citrate has the tendency to create a soaping effect once the emulsion is applied on the skin. This can be counteracted through the addition of co-emulsifiers.

Investigation of two natural emulsifier mixtures

In this study we set out to design two robust, versatile, and all-natural emulsifier blends. To achieve this we chose Glyceryl Stearate Citrate and combined it with the non-ionic Co-emulsifier Cetearyl Alcohol and then added either Glyceryl Laurate (Mixture A) or Glyceryl Behenate (Mixture B). The compositions of the two mixtures are as shown in Table 1.

We chose these compositions to investigate the effect of the carbon chain length of constituent 3 on the emulsion properties, such as stability, consistency, spreadability, richness, and others. By choosing very different fatty acid esters (Glyceryl Laurate: C12:0, Glyceryl Behenate: C22:0), we were curious to see in what way these properties were affected, if at all.

The choice to include not one, but two non-ionic co-emulsifiers is based on the theory that a densely packed water/oil interphase is instrumental for achieving highly stable emulsions. The anionic heads of the main emulsifier Glyceryl Stearate Citrate align at this interphase based on their hydrophilic/lipophilic preferences (Fig. 1, left), which induces electrostatic repulsion between these identically charged molecular sections, leading to interfacial gaps. Through the addition of the non-ionic co-emulsifier Cetearyl Alcohol, these gaps can be filled to some extent (Fig. 1, center), but the low hydrophilicity of the fatty alcohols is not enough to completely counteract the electrostatic forces. Therefore the second non-ionic co-emulsifier, Glyceryl Laurate or Glyceryl Behenate, is employed, which is able to close the remaining gaps and ensures a densely packed interphase (Fig. 1, right).

In order to test the emulsifier blends for application versatility and emulsion stability, emulsions with different oil phase compositions and oil phase sizes were prepared, and underwent stability testing according to standard centrifuge and prolonged warming storage protocols (Table 2).

In the following table, emulsions that remained stable are marked with a green dot and unstable emulsions are shown with a red dot. Stability tests were carried out for 3 months at 40 °C, the viscosity was measured at 3 different rotational speeds after defined periods of time and instabilities were checked each week.

Three different oils were employed in this study, which are considered to be among the most common oils used in natural cosmetic formulations: sunflower oil as a vegetable oil, jojoba oil as a wax oil, MCT oil, which is also known as neutral oil and consists of a mixture of medium-chain triglycerides, more specifically capric acid and caprylic acid. While in reality it is common to use oil mixtures in cosmetic formulations, in this principled study we wanted first to investigate if any general incompatibilities with certain oil types of different concentrations exist.

All formulations contained, apart from the emulsifier blend and the named oil, the following ingredients: Aqua, Xanthan Gum as gelling agent, Sodium Levulinate, Potassium Sorbate as the preservative system and Tocopherol as antioxidant for the oil phase.

In these stability studies it was found that both emulsifier blends produced stable emulsions with all oils, only showing weaknesses at low oil phase sizes and emulsifier-concentrations.

Sensory Study

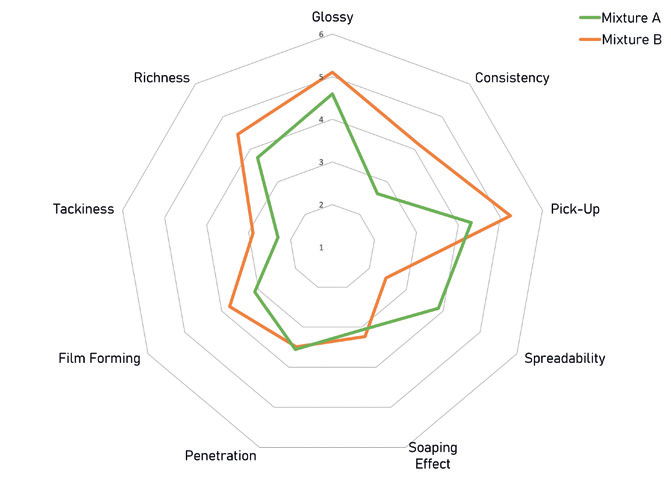

In order to analyze the sensory properties of mixtures A and B and clarify their specific differences, a trial was conducted with a panel of 47 people aged 18-72 years (29 W, 18 M). The volunteers were asked to compare the two O/W emulsions prepared with mixtures A and B (cream A and cream B) with regard to the categories shown in Figure 2.

It is evident that several categories showed a significant difference, specifically the consistency, pick-up, spreadability and the richness of the cream. Cream B was felt to be a rich cream that is more difficult to spread of the skin. Cream A was generally described as a light formulation and was easier to spread, less sticky and less film-forming compared to Cream B. Both formulations were perceived to possess very little soaping effect, and showed quick penetration.

It can be concluded that the addition of emulsifiers with longer c-chains (Glyceryl Behenate) will build a bigger body and therefore create higher consistency and pick-up compared to emulsifiers with a shorter c-chain (Glyceryl Laurate). Glyceryl Behenate will increase the filmforming effect and have a longer playtime on the skin resulting in a rich skinfeel. Glyceryl Laurate will have a lower viscosity, higher spread ability and a lighter skinfeel.Laurate)

To investigate the versatility of mixtures A and B, formulations of different types and viscosities were prepared (Table 3). Stable emulsions were obtained with both emulsifier blends, and viscosities ranged from very thick and highly viscous creams, such as body butters, to hair conditioners as well as light and low-viscosity emulsions such as sun sprays. Mixture B resulted in emulsions of higher viscosities compared to Mixture A.

Conclusion

The significance of emulsifier blends in personal care product manufacturing cannot be overstated. We have explored the pivotal role of these blends in enhancing formulation stability, performance, and sensory feel. From their ability to optimize texture and spreadability, to their capacity to accommodate diverse formulation requirements, emulsifier blends offer a versatile and effective solution for formulators facing the challenges of modern product development.

Building upon this foundation of understanding, we have chosen to commercialize mixtures A and B under the trade names Evicare® emulgiza light and Evicare® emulgiza rich. Both blends offer highly versatile application options and are able to produce stable emulsions under different conditions. We are confident that these emulsifier blends will not only streamline formulation processes but also enable the creation of next-generation personal care products that embody efficacy, safety, and sustainability.

We remain committed to advancing the science of formulation and driving positive change within the industry, and we look forward to the transformative impact that these blends will have on the landscape of personal care product manufacturing.

For more information concerning frame formulations and application contact us at info@evident-ingredients.com